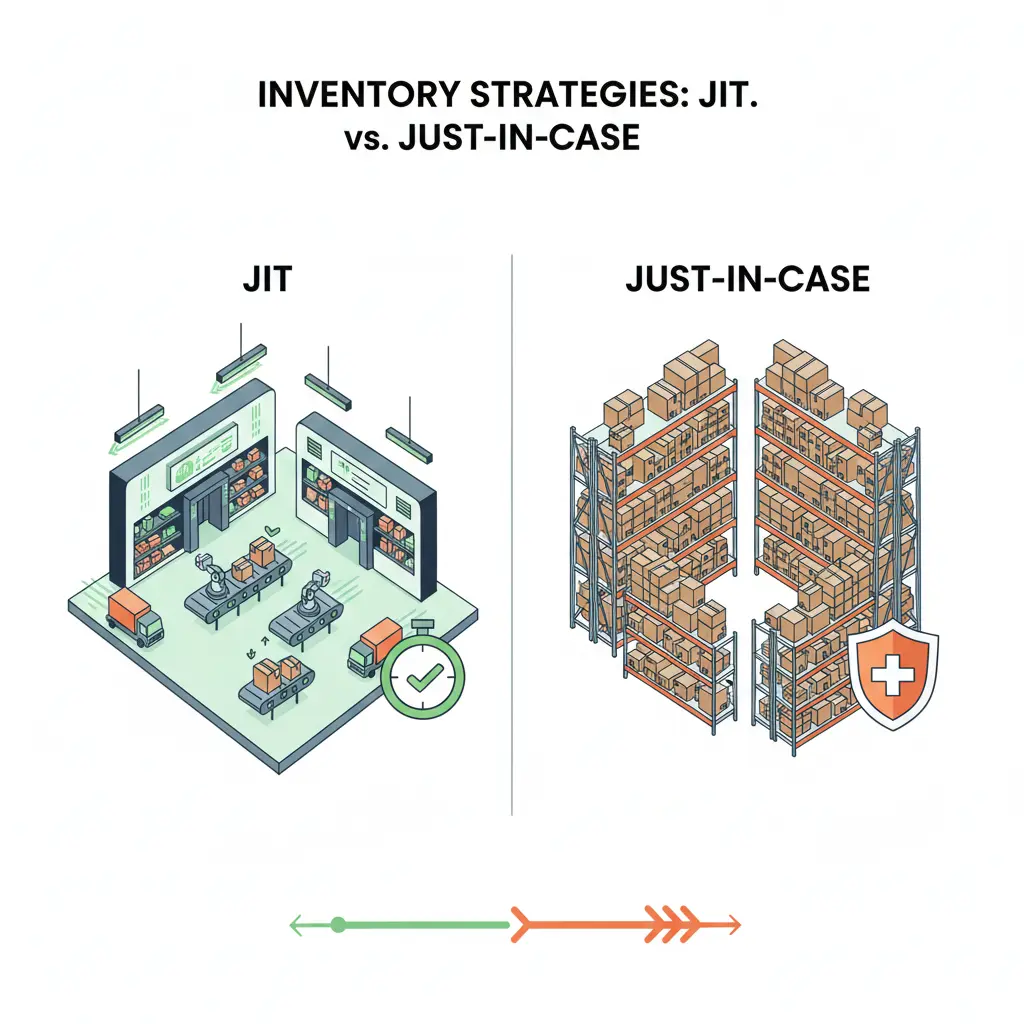

Inventory management is a critical aspect of supply chain optimization. Businesses often face the choice between Just-In-Time (JIT) and Just-In-Case inventory strategies, each with unique advantages and risks. Understanding the differences can help companies balance efficiency, cost, and operational resilience.

What is Just-In-Time (JIT) Inventory?

Just-In-Time (JIT) inventory is a strategy where companies maintain minimal stock levels and order goods only as needed. This approach reduces holding costs, minimizes waste, and ensures efficient use of resources. Companies using JIT rely heavily on accurate demand forecasting and strong supplier relationships.

Benefits of JIT Inventory

- Reduces storage and holding costs

- Minimizes inventory waste

- Improves cash flow

- Encourages lean operations

Risks of JIT Inventory

- Vulnerable to supply chain disruptions

- Requires precise demand forecasting

- Limited buffer for unexpected demand spikes

What is Just-In-Case Inventory?

Just-In-Case inventory is a strategy where companies maintain extra stock to prepare for unexpected demand or supply chain disruptions. This approach prioritizes business continuity over cost-efficiency, ensuring that products are available even in uncertain conditions.

Benefits of Just-In-Case Inventory

- Protects against supply chain disruptions

- Meets unexpected demand quickly

- Provides operational security

Risks of Just-In-Case Inventory

- Higher holding and storage costs

- Increased risk of inventory obsolescence

- Potential cash flow challenges

JIT vs. Just-In-Case: Key Differences

| Factor | Just-In-Time (JIT) | Just-In-Case |

|---|---|---|

| Inventory Levels | Minimal | High |

| Focus | Efficiency | Security |

| Cost | Lower | Higher |

| Risk | Supply chain disruptions | Obsolescence & storage costs |

| Ideal For | Stable demand, reliable suppliers | Uncertain demand, supply chain volatility |

Which Strategy Should You Choose?

The choice between JIT vs. Just-In-Case inventory depends on your business model, market conditions, and risk tolerance.

- Businesses with predictable demand and strong supplier networks often benefit from JIT inventory, as it reduces costs and improves operational efficiency.

- Companies operating in volatile markets or with unpredictable supply chains may prefer Just-In-Case inventory to ensure continuity and avoid stockouts.

Some businesses adopt a hybrid approach, maintaining minimal stock for fast-moving items (JIT) while keeping reserves of critical components (Just-In-Case).

Conclusion

Understanding Just-In-Time vs. Just-In-Case inventory strategies is essential for effective inventory management. Both approaches have pros and cons, and the right choice depends on your business goals, demand patterns, and supply chain reliability. By carefully evaluating these strategies, companies can optimize costs, improve efficiency, and safeguard against disruptions.

Leave a Reply