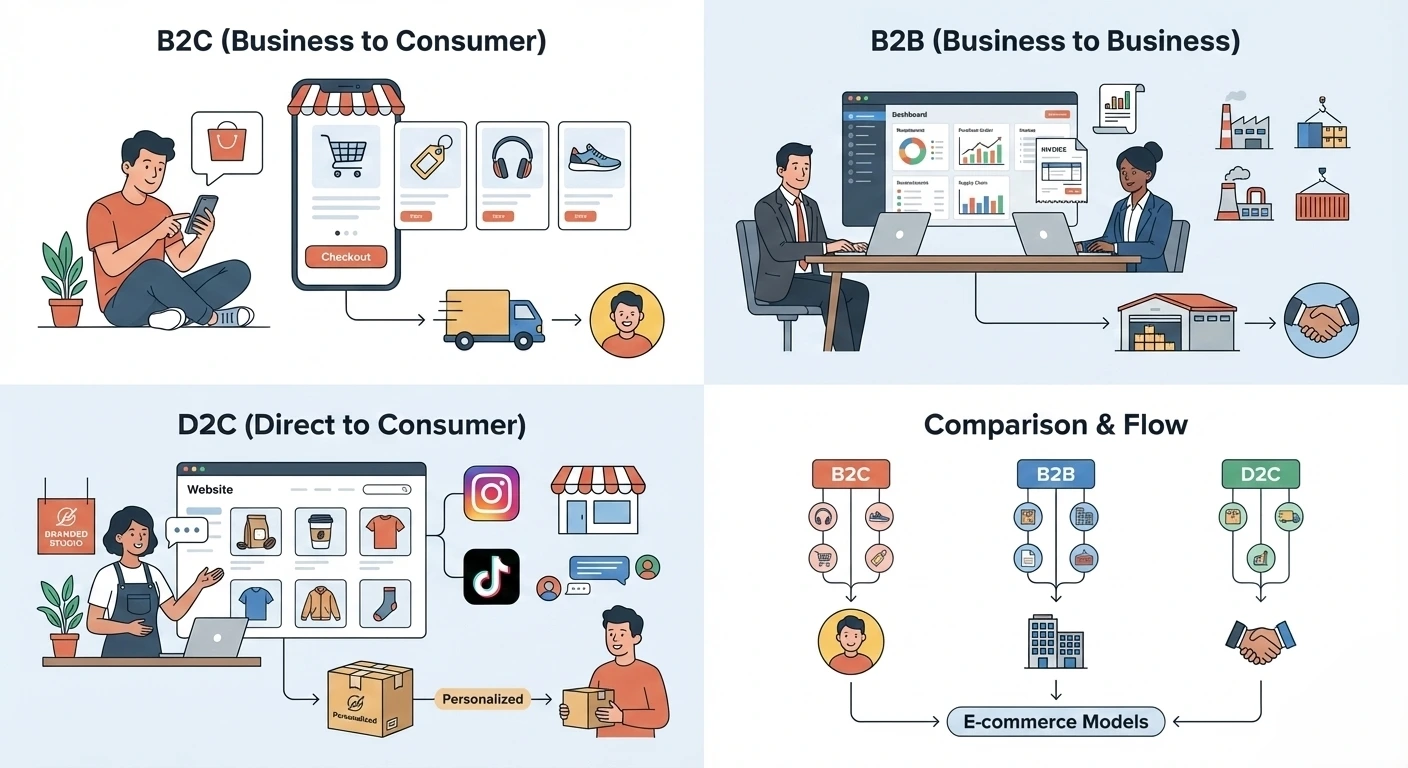

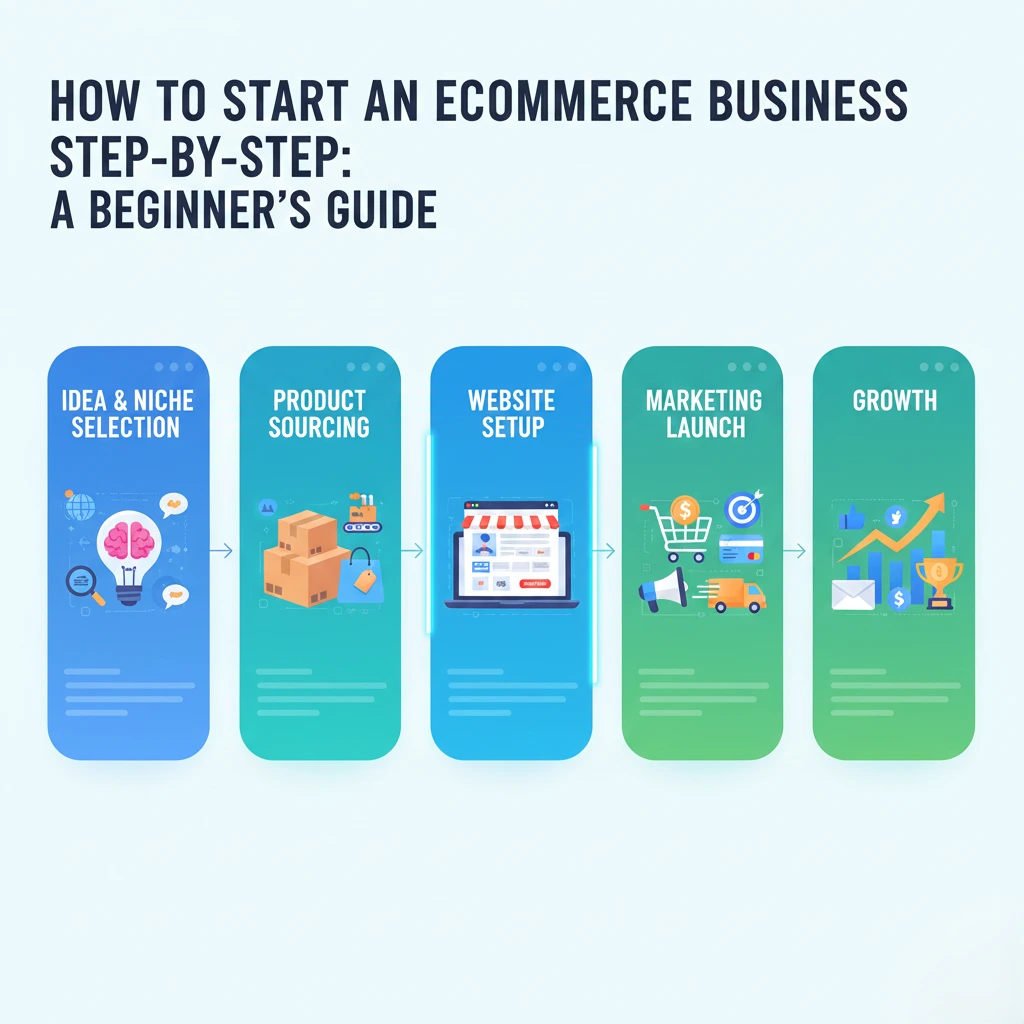

For ecommerce brands, one of the most important strategic decisions is choosing where to sell. Selling on Amazon vs D2C ecommerce websites is not a matter of right or wrong, but of goals, margins, and long-term brand vision. While Amazon offers instant scale and trust, Direct-to-Consumer (D2C) websites provide control and customer ownership. Understanding the strengths and limitations of both models helps brands build a sustainable ecommerce strategy.

Understanding the Amazon Marketplace Model

Amazon is the world’s largest online marketplace, attracting millions of high-intent shoppers daily. For new and growing brands, selling on Amazon can feel like a fast track to revenue.

Advantages of Selling on Amazon

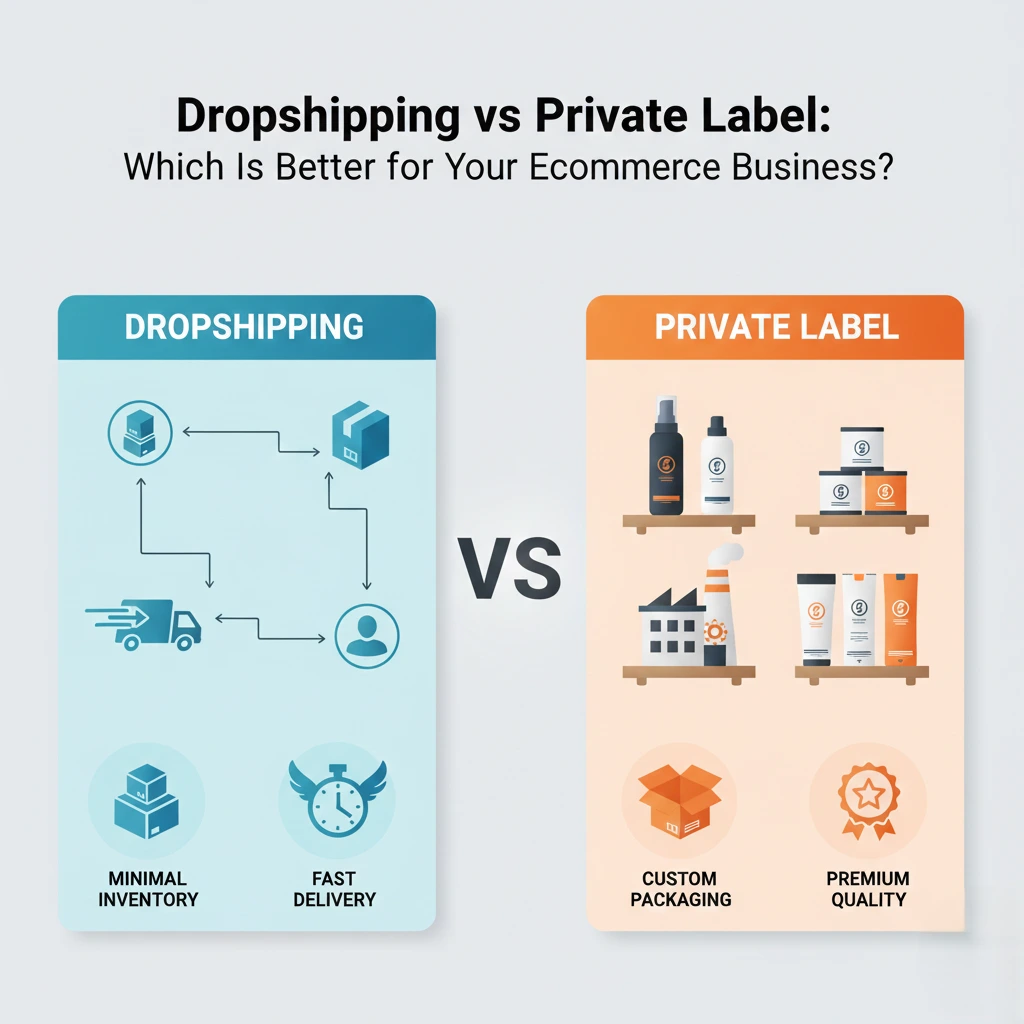

One of the biggest benefits of selling on Amazon is access to a massive customer base. Amazon handles trust, logistics, and payments, reducing operational friction. Programs like Fulfillment by Amazon (FBA) simplify storage, shipping, and returns, allowing brands to focus on sourcing and marketing.

Amazon also excels at product discovery. Shoppers often search Amazon directly rather than Google, giving sellers exposure to buyers who are already ready to purchase.

Challenges of Selling on Amazon

Despite its reach, Amazon comes with trade-offs. High seller fees, intense competition, and limited brand differentiation can impact profitability. Brands also have minimal access to customer data, making it difficult to build long-term relationships. Algorithm changes or account suspensions can significantly affect sales overnight.

Understanding the D2C Ecommerce Website Model

A D2C ecommerce website allows brands to sell directly to consumers through their own online store, typically powered by platforms like Shopify or WooCommerce.

Advantages of D2C Ecommerce Websites

The biggest advantage of D2C is control. Brands own the customer relationship, data, and experience. This enables personalized marketing, email automation, loyalty programs, and better customer lifetime value.

Margins are often higher on D2C ecommerce websites since there are no marketplace commissions. Brands can also fully control pricing, branding, storytelling, and user experience, which is essential for long-term brand building.

Challenges of the D2C Model

D2C ecommerce requires more effort upfront. Brands must invest in traffic acquisition through SEO, paid ads, social media, and content marketing. Logistics, returns, and customer support are also the brand’s responsibility unless outsourced. Trust takes time to build, especially for new or unknown brands.

Amazon vs D2C Ecommerce Websites A Direct Comparison

Customer Ownership

When comparing Amazon vs D2C ecommerce, customer ownership is a key differentiator. Amazon controls customer data, while D2C brands can nurture direct relationships and remarket effectively.

Cost and Margins

Amazon’s fees reduce margins but lower operational complexity. D2C websites offer better margins but require ongoing marketing and technology investment.

Brand Building

Amazon prioritizes products over brands, making differentiation difficult. D2C ecommerce websites allow brands to tell their story, build community, and create emotional connections.

Scalability and Risk

Amazon enables rapid scaling but comes with platform dependency risks. D2C growth is slower but more stable and defensible over time.

Which Model Is Right for Your Ecommerce Business

The choice between selling on Amazon vs D2C ecommerce websites depends on business objectives. Brands focused on quick sales and operational simplicity may benefit from Amazon. Brands aiming for long-term growth, loyalty, and brand equity often prioritize D2C.

Many successful ecommerce businesses adopt a hybrid strategy. Amazon is used for customer acquisition and volume, while D2C channels focus on retention, upselling, and brand building.

Final Thoughts on Amazon vs D2C Ecommerce

Selling on Amazon and running a D2C ecommerce website are not mutually exclusive. Amazon offers reach and convenience, while D2C provides control and sustainability. The most resilient ecommerce brands understand the strengths of both models and align them with their growth strategy. By balancing scale with ownership, businesses can build profitable and future-ready ecommerce operations.